Design of Superalloy Powder Material

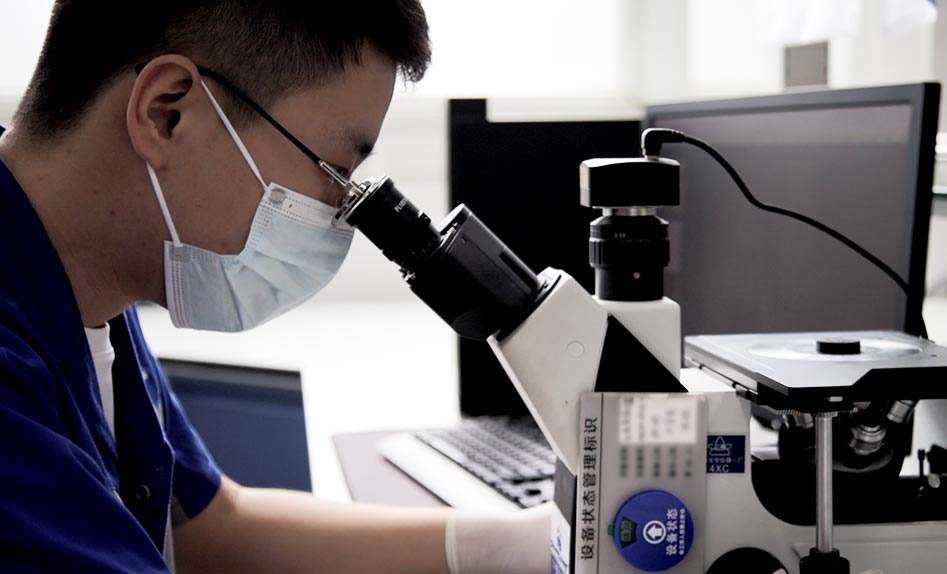

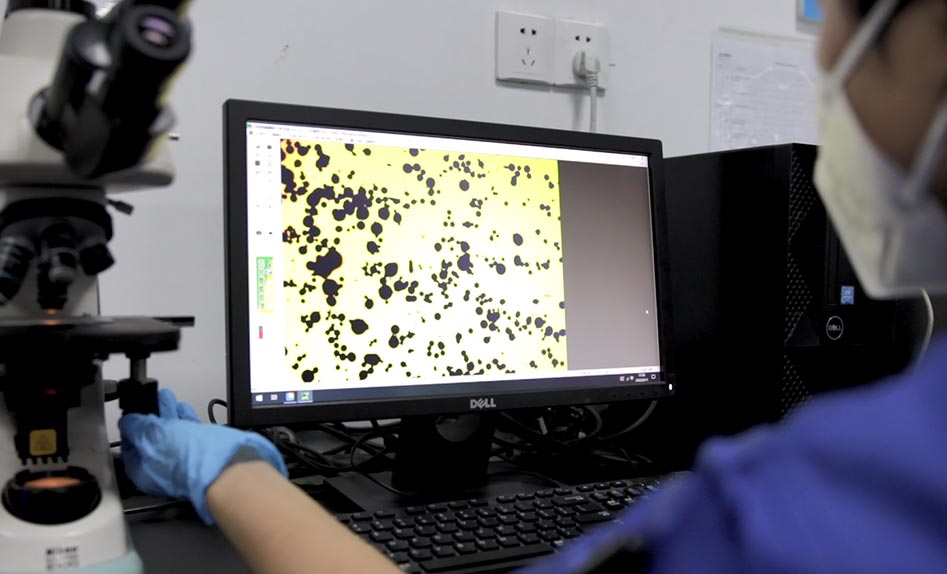

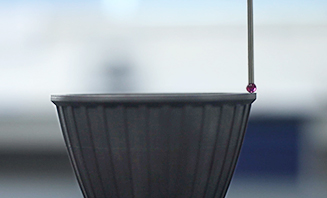

Aiming at the problems of internal micro-cracking and low high-temperature performance of superalloy powder material, we carry out the melting and composition optimization of ultra-high-purity superalloys and develop more than 20 kinds of superalloy materials such as Hastelloy X,In625, GH3230, HA188, In718, GH4099, etc.