2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Recently, AVIMETAL’s independently developed integrated, high-precision Selective Laser Melting (SLM) equipment MT400M has achieved a breakthrough in major technical equipment, successfully obtaining the 2024 First Major Technical Equipment certification, demonstrating the company’s comprehensive equipment capabilities.

Major technical equipment is a national treasure, which is related to comprehensive national strength and national security. The first major technical equipment certification is an authoritative recognition of equipment with significant advantages in technological innovation, product performance, and market application.

The MT400M was officially launched at the 25th Jinjiang Shoe (Sports) Expo, customized for industrial users in shoe molds, 3C, and automotive sectors. Benchmarking and integrating mainstream industry design advantages, its comprehensive performance shows clear superiority. After months of development, the equipment underwent a complete upgrade at Formnext 2024 in Germany, featuring larger forming size, more compact and flexible structure, more convenient operation, and higher integration level, continuously maintaining industry-leading technological advantages.

The MT400M adopts the selective laser melting (SLM) forming technology, with a forming size of 420×350×400mm (X×Y×Z). The equipment is standardly equipped with a 4-laser technology and can be optionally equipped with 2, 3, or 6-laser modules. The misalignment deviation of each laser overlap area is within 5μm, and it is matched with the multi-galvanometer scanning accuracy calibration function to ensure consistent and stable full-format printing. The equipment is equipped with the variable layer thickness printing function. Under the standard 4-laser solution, the forming efficiency can reach 100cm³/h, helping users efficiently produce complex and precise structures.

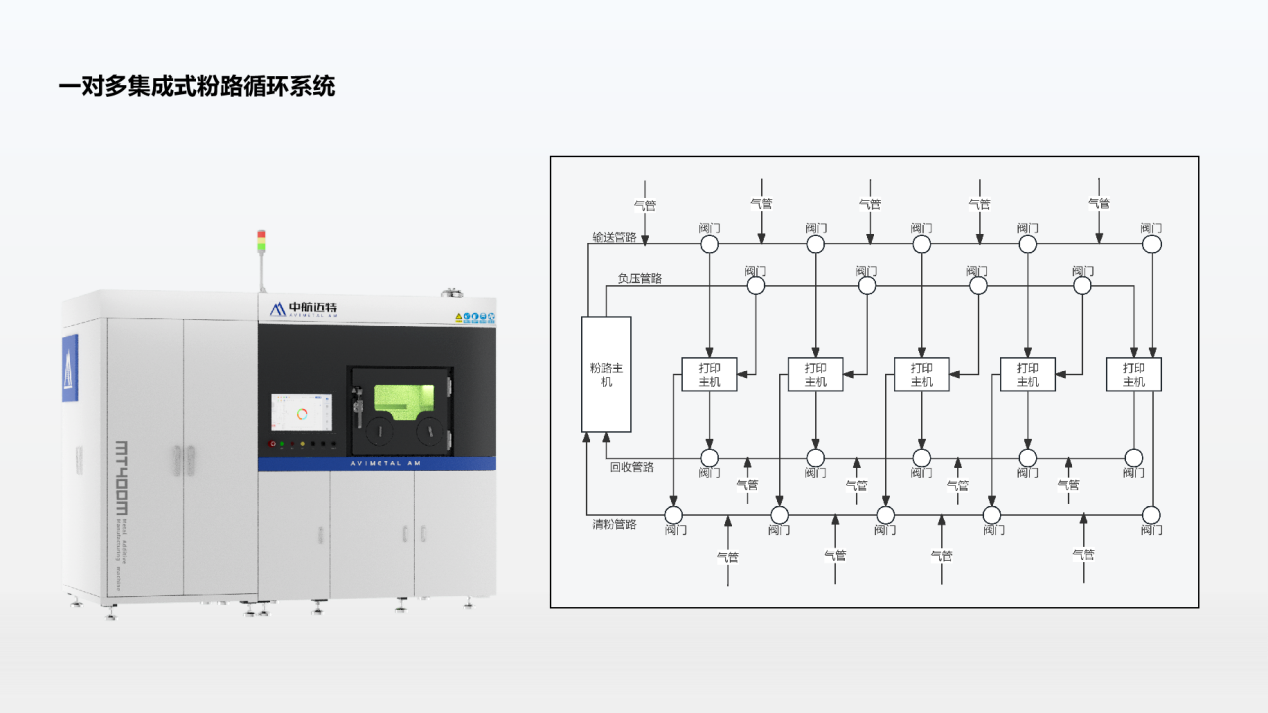

The MT400M is equipped with the self-developed Avi-Pretreatment preprocessing software and Avi-Control equipment integrated control system software. All process parameters are designed with open-source, breaking through the “bottleneck” problem of software, and the operation process of the equipment is highly intelligent. At the same time, the equipment supports the self-developed Avi-APSS integrated powder circulation system and MT-PLM 3D printing full-life cycle management system. Under the condition of printing with the same powder, multiple sets of equipment can operate simultaneously, and all production links are fully interconnected and data-shared, meeting the requirements of continuous and large-scale production of industrial users.

Currently, MT400M has been successfully applied in multiple fields including 3C and shoe molds, effectively demonstrating domestic metal 3D printing equipment technological advantages and achieving core equipment localization.

In September 2022, AVIMETAL grandly released four selective laser melting equipment products and officially entered the field of SLM metal 3D printing equipment. It has always been focused on the design and manufacturing of high-precision and multi-laser printing equipment, and has successively developed more than ten models of metal 3D printers. It has achieved self-control of core components and software systems of metal 3D printing equipment, and continuously provides high-end equipment support for manufacturing upgrades and the industrialization development of end-users.

Leveraging this certification, AVIMETAL will continue to drive core technological innovation in metal 3D printing equipment, enhancing product industrialization and technological application depth, and collaborating with industry partners to advance global smart manufacturing.